Are you wondering how far a hollow core slab can stretch without support? These slabs can impressively span up to 16 meters while supporting loads of 2.3 KN/sq.m.

Our article breaks down the key factors that influence their reach, ensuring your next construction project stands on solid ground.

Key Takeaways

- Hollow core slabs can span up to 16 meters, supporting loads of 2.3 KN/sq.m, with thicknesses between 15 cm and 50 cm ideal for different construction needs.

- Factors like the slab’s depth, type and amount of reinforcement, specific load requirements, and concrete quality influence the maximum span length of hollow core slabs.

- Standard depths for hollow core slabs include 8”, 10”, and 12”, correlating with standard maximum spans ranging from up to 10m to up to 16m respectively.

- Reinforcing steel wire rope is used in hollow core slabs to increase their bending resistance and support heavy loads over long spans safely.

- High – quality concrete must meet industry standards such as BS 8110 for strength and fire resistance ensuring structural integrity over time.

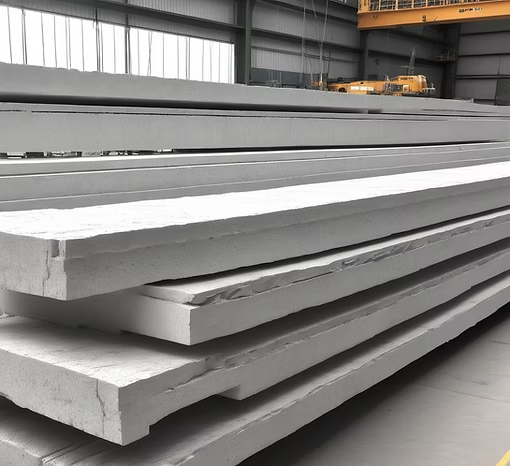

What is a Hollow Core Slab?

A hollow core slab is a precast, prestressed concrete slab with tubular voids running the length of the slab. These voids reduce the weight of the slab and provide efficient material usage, making them ideal for residential applications.

Definition

Hollow core slabs are precast concrete floor panels with tubular voids extending the full length of each panel, making them lighter and more efficient than solid concrete. These structural elements efficiently support loads over long spans without requiring intermediate supports and thus provide substantial space flexibility for buildings.

Their design incorporates reinforcing strands, typically made of steel wire rope, which grant the slab additional strength to resist bending. With standard widths around 120 cm and varying depths from 15 cm up to 50 cm, hollow core slabs cater to a range of applications in building construction.

These concrete elements stand out for their fire resistance qualities—offering at least one hour’s worth—and they come in standard depths such as 8”, 10” or 12”. Builders favor these robust components because they can achieve maximum spans reaching up to an impressive 20 meters under specific loading conditions while maintaining a load capacity of about 2.3 KN/sq.m.

Hollow core slabs conform to established standards like BS 8110 for assured safety and performance in residential applications, commercial projects, and beyond.

Types of Hollow Core Slabs

Hollow core slabs are classified into the following types:

- Standard Hollowcore Planks: Typically 120 cm wide with thicknesses ranging from 120 – 500 mm, allowing spans between 5 – 20 m.

- Fire-Resistant Hollowcore Planks: Designed to provide a minimum fire resistance of 1 hour, meeting safety regulations.

- Reinforced Hollowcore Slabs: These slabs incorporate reinforcing steel wire rope to enhance bending resistance and load-bearing capacity.

- Customized Hollow Core Slabs: Available in various widths and depths, tailored to specific project requirements, offering flexibility in design and construction.

Factors Affecting the Maximum Span of a Hollow Core Slab

The maximum span of a hollow core slab is influenced by several factors including the depth of the slab, type and amount of reinforcement, load requirements, and quality and type of concrete used in its construction.

These factors play a crucial role in determining the overall strength and load-bearing capacity of the hollow core slab.

Depth of the slab

Hollow core slabs can vary in thickness from 120mm to 500mm, depending on the project’s requirements. The typical span of hollow core slabs falls between 5 and 20 meters, with different depths chosen based on plank spans and loading.

These planks are manufactured in standard depths of 8”, 10”, and 12”. For a project requiring larger spans or heavier loads, a greater depth may be necessary to ensure structural integrity.

The hollow core slab depth directly impacts its load-bearing capacity, ensuring that it meets safety standards while offering clear spans for construction projects. Designing the slab’s depth according to building specifications is essential for achieving the required load-bearing capacity and overall structural stability.

Type and amount of reinforcement

To enhance the load-bearing capacity of hollow core slabs, reinforcing steel wire rope is used to provide bending resistance. The amount and type of reinforcement play a crucial role in determining the strength and durability of the slabs.

By incorporating the right level of reinforcement based on structural engineering requirements, hollow core slabs can effectively support heavy loads over long spans, making them suitable for various construction applications.

Additionally, adhering to standards such as BS 8110 ensures that the design and quantity of reinforcement are in line with industry regulations, guaranteeing structural integrity and safety.

Load requirements

Reinforcement and depth affect the load requirements for hollow core slabs. The required bearing capacity is influenced by the type and amount of reinforcement, as well as the depth of the slab.

Load span tables are essential for determining how much weight a hollow core slab can support over various spans. It’s important to consider these factors when designing and installing precast concrete slabs for optimal load-bearing capacity.

Quality and type of concrete

To ensure the adequate load-carrying capacity and fire resistance of hollow core slabs, the quality and type of concrete play a crucial role. The concrete mix must meet the specified requirements for strength, durability, and workability as per industry standards.

Proper concrete consolidation during pouring is essential to prevent voids or honeycombing within the slab structure. Additionally, conducting regular quality control tests ensures that the concrete meets the necessary compressive strength and other performance criteria, allowing for reliable long-term structural integrity.

The type of concrete used should be compatible with any additional admixtures or additives required for specific project needs. Careful consideration of materials such as lightweight aggregates or fibers can significantly impact both the weight-to-strength ratio and overall durability of hollow core slabs while adhering to designated design codes like BS 8110.

Maximum Span of a Hollow Core Slab

The maximum span of a hollow core slab varies based on factors such as depth, reinforcement, load requirements, and the type of concrete used. To find out more about the standard spans for different depths and other factors that can affect the span length, keep reading!

Standard spans for different depths

Hollow core slabs are engineered for high-performance structural efficiency, enabling them to cover significant spans. Below is a table summarizing standard span lengths correlating with various slab thicknesses.

| Slab Thickness (inches) | Standard Maximum Span (meters) |

|---|---|

| 8” (approx. 200 mm) | up to 10m |

| 10” (approx. 250 mm) | up to 14m |

| 12” (approx. 300 mm) | 12” (approx. 300 mm) |

| 15” (approx. 380 mm) | up to 18m |

| 20” (approx. 500 mm) | up to 20m |

Each slab is designed to withstand a specific load requirement, with depth enhancing the ability to span wider gaps. Depths typically range from 8 inches to 20 inches, catering to a span range from 5 meters to the maximum of 20 meters. Utilization of quality concrete and reinforcement ensures these slabs meet standard building code requirements, such as BS 8110, to maintain safety and integrity across these distances.

Factors that can affect the span

The factors affecting the span of a hollow core slab are:

- The depth of the slab impacts its maximum span length.

- The type and amount of reinforcement used in the design influence the load – bearing capacity.

- The specific load requirements for the structure can affect the maximum span.

- The quality and type of concrete used in construction play a significant role in determining the maximum span length.

Conclusion

In conclusion, hollow core slabs can achieve a maximum span of 16 meters with a capacity of 2.3 KN/sq.m. The typical thickness ranges from 15 cm to 50 cm, providing clear spans ranging from 5 to 20 meters.

Factors such as depth, reinforcement type and load requirements impact the maximum span capability of hollow core slabs. These design considerations contribute to their versatility in construction projects.

Looking for a precast concrete supplier for your next project. Contact Vintage Cast today and get a quote.

FAQs

1. What determines the maximum span of a hollow core slab?

The maximum span of a hollow core slab depends on factors like the depth of slabs, load-bearing capacity, and span to depth ratio used in its design.

2. Can the depth of a hollow core slab affect its span length?

Yes, generally, increasing the depth of a hollow core slab can allow it to span longer distances without additional support.

3. What minimum bearing is required for installing a hollow core slab?

For proper installation, there must be adequate minimum bearing at each end of the slab to safely transfer loads to support structures.

4. Do connection details matter for the span length of hollow core slabs?

Connection details are crucial because they ensure that individual slabs work together effectively in beam and block systems, affecting their overall span capabilities.

5. Are reinforced concrete and construction materials important for my floor system’s maximum span?

Absolutely! The quality and type of reinforced concrete and other construction materials contribute significantly to determining your floor system’s strength and maximum allowable span.

Recent Posts

Why Landscaping Pros Prefer Precast Concrete Over Poured-in-Place

Why & How is Precast Concrete Prestressed?