Precast concrete panels are key players in modern construction, but how long can we expect them to last? These durable building blocks are designed for a century of use if they’re made and cared for correctly.

Our blog post dives into the factors that give these panels their strength and longevity, helping you understand your investment. Keep reading to discover the secrets behind their impressive lifespan.

Key Takeaways

- Precast concrete panels have an average lifecycle of 50 to 100 years if installed and maintained correctly.

- The quality of materials, including high-grade concrete and corrosion-resistant reinforcement bars, heavily influence the panels’ durability.

- Proper installation is key; incorrect placement can lead to premature deterioration and structural issues over time.

- Environmental factors such as extreme weather, pollutants, and salts can affect lifespan—protective measures are necessary for harsh climates or coastal areas.

- Regular maintenance like cleaning, applying protective coatings, inspections for damage, alongside prompt repairs extend the panel’s service life.

Understanding Precast Concrete Panels

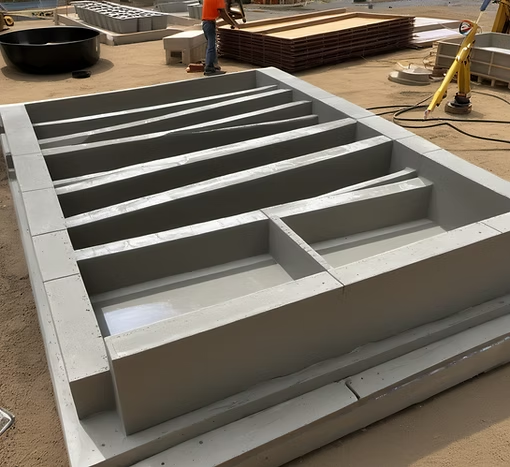

Precast concrete panels are manufactured off-site and transported to the construction site for installation. The production process involves pouring concrete into molds, allowing it to cure, and then lifting the precast panels into place.

Definition

Precast concrete panels are structural components cast and cured in a controlled factory environment before being transported to the construction site for installation. These panels can be used as walls, floors, or roofs in buildings and are known for their durability and longevity.

The precise manufacturing process of precast concrete allows for the reinforcement of materials, which contributes to its impressive strength and weather resistance. As building material technology advances, these concrete products are designed with an expected lifespan reaching up to 100 years or more under optimal conditions.

Cast in various shapes and sizes depending on architectural design needs, each panel includes steel reinforcing bars that increase its load-bearing capacity. This combination of high-quality cement longevity and reinforced integrity makes them popular choices for a broad range of applications ranging from residential housing to large infrastructural projects requiring long-lasting concrete solutions.

Production process

The production process of precast concrete panels begins with the creation of molds. Concrete is then poured into the forms and cured in a controlled environment. The panels are then demolded, finished, and stored until they are ready for transportation and installation.

- Molds are carefully designed to ensure the desired shape and dimensions of the panels.

- High – quality concrete mixtures are prepared and poured into the molds to form the panels.

- Curing takes place in a controlled environment to optimize strength and durability.

- Once cured, the panels are removed from the molds for further finishing and detailing.

- Finishing includes surface treatments, texturing, and applying protective coatings as needed.

- After completion, the panels undergo thorough quality control checks before being stored for future use or transported to construction sites.

- Precast concrete panels are transported to their destination using specialized equipment designed for safe handling and positioning at construction sites.

Factors Affecting the Life Expectancy of Precast Concrete Panels

The quality of materials used and proper installation are crucial factors affecting the lifespan of precast concrete panels. Environmental factors such as exposure to harsh weather conditions also play a significant role in their longevity.

Quality of materials used

Quality materials are essential for precast concrete panels to achieve their intended life expectancy. The type and grade of concrete, as well as the quality of reinforcement used, directly impact the durability of the panels.

Properly graded aggregates and high-quality cement contribute to the strength and longevity of precast concrete. Additionally, using corrosion-resistant reinforcing materials such as epoxy-coated or stainless steel rebar can significantly enhance the lifespan of precast concrete panels, especially in environments with high exposure to moisture or chloride.

Furthermore, attention to detail during the production process is crucial in maintaining consistent material quality across all panels. Ensuring that proper curing methods are employed and monitoring mix designs for optimal performance helps guarantee that each panel meets stringent quality standards.

Proper installation

Proper installation of precast concrete panels is crucial for ensuring their longevity. Correctly positioning and securing the panels during installation can prevent structural issues and prolong their service life.

Additionally, using high-quality materials and following best practices during the construction process can help mitigate potential degradation over time, contributing to the overall durability of precast concrete panels.

Environmental factors also play a role in the installation process, as exposure to harsh weather conditions or other external elements can impact the long-term performance of the panels.

Environmental factors

Environmental factors play a crucial role in determining the life expectancy of precast concrete panels. Exposure to harsh weather conditions, such as extreme temperatures, high humidity, and heavy rainfall, can accelerate the deterioration of concrete structures over time.

Additionally, corrosive substances like industrial pollutants and salts can contribute to the degradation of precast concrete panels. Proximity to bodies of water or coastal areas may also increase the risk of erosion due to saltwater exposure.

It’s important to consider these environmental variables when assessing the long-term performance and durability of precast concrete panels.

Furthermore, proper consideration must be given to environmental factors during the design and construction phases to mitigate potential risks and ensure an extended service life for precast concrete components.

Implementing protective coatings, using corrosion-resistant materials, and incorporating effective drainage systems are essential strategies for enhancing the resilience of precast concrete panels against environmental challenges.

The Average Lifespan of Precast Concrete Panels

The average lifespan of precast concrete panels varies depending on various factors such as the quality of materials used, proper installation, and environmental conditions. Real-world examples can provide insight into the expected lifespan of precast concrete panels in different situations.

Expected lifespan

Precast concrete panels typically have a lifespan of around 50 to 100 years if properly constructed and maintained. Factors such as the quality of materials, installation techniques, and environmental conditions can influence their longevity.

Modern concrete structures are designed to last for at least 100 years with proper maintenance, making them a durable option for construction projects. Although signs of deterioration may start to show after about 50 years, regular maintenance and repairs can help extend the life expectancy of precast concrete panels.

Reinforced concrete buildings and cement houses also have their own specific life expectancies, depending on factors like maintenance and construction quality. Properly built precast structures do not generally require maintenance or repairs during their expected lifespan, making them an economical long-term choice for construction projects.

Real-world examples

To exemplify the longevity of precast concrete panels, numerous real-world instances demonstrate their exceptional durability. For instance, the Pantheon in Rome stands as a testament to the long-lasting quality of concrete.

This iconic structure was built over 2000 years ago with a concrete dome that still stands tall today, showcasing the enduring nature of well-constructed concrete. Similarly, many modern infrastructure projects rely on precast concrete elements for their reliability and longevity.

Bridges like the Tunkhannock Viaduct in Pennsylvania have utilized precast components to ensure structural integrity and endurance against environmental factors such as heavy loads and harsh weather conditions.

Moreover, residential buildings constructed using precast panels have also showcased impressive life expectancy. Many housing developments across the United States incorporate precast concrete walls that have maintained their strength and appearance for several decades without significant signs of degradation.

Extending the Life of Precast Concrete Panels

Ensure proper maintenance, use reinforcements and additives when necessary, and promptly address any repairs or replacements to extend the life of precast concrete panels.

Proper maintenance

Proper maintenance is essential to ensure the longevity of precast concrete panels. It involves:

- Regular inspections to identify any signs of wear and tear, such as cracks or spalling, that need immediate attention and repair.

- Cleaning the panels periodically to remove dirt, pollutants, and other contaminants that can degrade the surface and compromise durability.

- Applying protective coatings to enhance resistance against environmental factors including moisture, chemicals, and UV exposure.

- Implementing preventive measures such as sealing joints and edges to prevent water infiltration which can lead to corrosion of reinforcement.

- Conducting structural assessments by qualified professionals to address any potential issues before they escalate and affect the overall lifespan.

- Following manufacturer’s guidelines for maintenance routines specific to the type of precast concrete panels used in a building or structure.

- Repairing any damage promptly with compatible materials and techniques recommended by experienced professionals to maintain structural integrity.

Reinforcements and additives

Reinforcements and additives play a crucial role in extending the life expectancy of precast concrete panels. By incorporating steel reinforcements, these panels gain increased strength and resistance to environmental factors, contributing to their longevity.

Additionally, additives such as fly ash or silica fume enhance the durability of the concrete by reducing permeability and increasing resistance to chemical attacks, ensuring a longer service life for the panels.

Furthermore, utilizing corrosion-resistant reinforcements alongside appropriate additives can significantly improve the overall performance and lifespan of precast concrete panels.

Repairs and replacements

- Regular inspections should be conducted to identify any areas where repairs or replacements are needed.

- Damaged or deteriorating panels should be promptly repaired or replaced to maintain the structural integrity of the building.

- Repairs should be carried out using high – quality materials to ensure longevity and durability.

- In cases where replacement is necessary, new panels should be carefully installed following proper construction techniques.

- It’s essential to consider factors such as the quality of materials and environmental conditions when conducting repairs or replacements.

- Proper maintenance and timely repairs can help extend the overall lifespan of precast concrete panels.

Conclusion

In summary, precast concrete panels can have a lifespan of 50 to 100 years with proper construction and maintenance. Factors such as quality materials, correct installation, and environmental conditions play crucial roles in determining their longevity.

Reinforcements, proper maintenance, and repairs when needed can help extend the life expectancy of precast concrete panels. Understanding these factors is essential for ensuring the durability and long-term performance of precast concrete structures in various applications.

For your precast concrete needs, reach out to Vintage Cast today!

FAQs

1. How long do precast concrete panels last?

The expected lifespan of precast concrete products, like panels, typically ranges from 50 to 100 years due to their reinforced concrete durability and resistance to degradation.

2. What makes precast concrete so durable?

Precast concrete’s strength comes from its manufacturing process which provides structural engineering benefits, making it a long-lasting construction material with high durability.

3. Can weather affect the longevity of precast concrete structures?

Yes, even though precast concrete is a durable building material, extreme weather can impact the service life of precast concrete by causing wear over time.

4. Do all precast concrete panels have the same life expectancy?

No, the life expectancy of precast concrete panels can vary based on factors like quality of materials used, environmental conditions, and how well they are maintained.

5. How does the strength of precast compare to other building materials?

Precast concrete components generally offer greater long-term performance and longevity compared to many other types of building materials thanks to their robustness and structural lifespan.

Recent Posts

Why Landscaping Pros Prefer Precast Concrete Over Poured-in-Place

Why & How is Precast Concrete Prestressed?